If you have any questions please contact us!

In the fast-paced world of manufacturing and logistics, efficiently and reliably packaging products into cartons is crucial. Carton packing machines automate this vital step, boosting productivity, ensuring consistency, and reducing labor costs. This comprehensive guide explores everything you need to know about these essential workhorses of the packaging line.

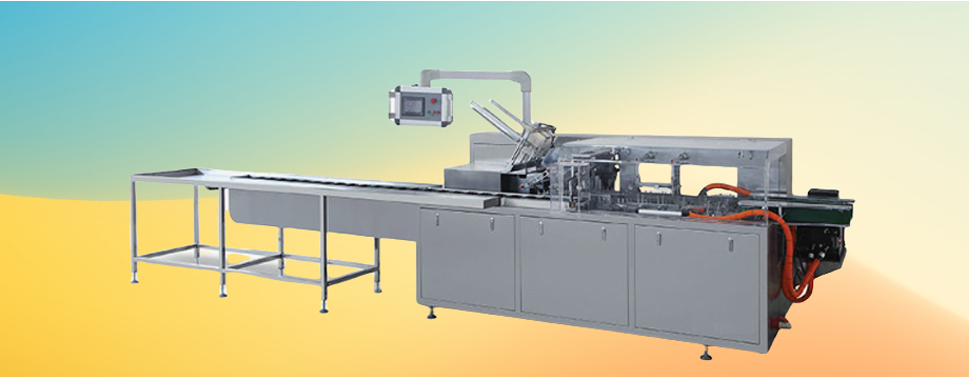

A carton packing machine is an automated system designed to erect, load, seal, and sometimes label corrugated cardboard cartons or boxes. It takes flat, folded carton blanks (or pre-glued cases), forms them into three-dimensional boxes, inserts the product, and securely closes the carton, ready for palletizing and shipping. These machines handle a vast array of products, from food and beverages to pharmaceuticals, electronics, and consumer goods.

1. Carton Magazine

This is the storage area where flat carton blanks are held. It is designed to feed the cartons one by one into the erecting mechanism. The magazine can be of different sizes and capacities depending on the model of the machine and the size of the cartons.

2. Carton Erecting Unit

This component is responsible for converting the flat carton blank into a three-dimensional box. It may use vacuum cups to pick up the carton blank, then mechanical fingers or guides to fold the sides and bottom of the carton into the correct shape.

3. Product Handling System

This includes the conveyors, chutes, and mechanical arms that transport the products to the packing station. The product handling system must be adjustable to accommodate different product sizes and shapes.

4. Packing Station

This is where the actual loading of products into the carton takes place. It is equipped with sensors and guides to ensure that the products are placed correctly inside the carton. The packing station may also have a mechanism to count the number of products being loaded to ensure the correct quantity is packed in each carton.

5. Sealing Unit

After the carton is filled with products, the sealing unit comes into action. There are different types of sealing mechanisms, such as tape sealing, where adhesive tape is applied to the top and bottom flaps of the carton; glue sealing, where a layer of adhesive is applied to the flaps and they are pressed together; and staple sealing, where staples are used to secure the flaps.

6. Control Panel

The control panel is the brain of the carton packing machine. It is usually a touch-screen interface that allows the operator to set parameters such as carton size, product type, packing speed, and sealing method. The control panel also displays real-time information about the machine's operation, such as the number of cartons packed, any errors or malfunctions, and the status of each component.

1. Pre - operation Preparation

Check the Machine: Before starting the machine, visually inspect all components to ensure that there are no loose parts, damaged belts, or blocked sensors. Check the carton magazine to ensure that there are enough carton blanks and that they are properly aligned.

Set the Parameters: Using the control panel, set the appropriate parameters for the product and carton being used. This includes the carton size (length, width, height), product type (size, weight, shape), packing speed, and sealing method. Make sure to input the correct values to avoid any errors during the packing process.

Load the Cartons and Products: Load the flat carton blanks into the carton magazine and ensure that the product handling system is loaded with the products to be packed. Make sure that the products are properly aligned and that the conveyors are running smoothly.

2. Starting the Machine

Turn on the power switch of the machine. The control panel will light up, and the machine will perform a self - test. Wait for the self - test to complete, and make sure that there are no error messages displayed on the control panel.

Press the "Start" button on the control panel. The machine will start to operate, and the carton erecting unit will begin to retrieve carton blanks from the magazine and erect them into boxes. The product handling system will start to transport the products to the packing station, and the packing and sealing processes will begin.

3. Monitoring the Operation

During the operation, closely monitor the machine's performance. Keep an eye on the control panel for any error messages or warnings. Observe the packing process to ensure that the products are being placed correctly into the cartons, the cartons are being sealed properly, and there are no jams or misalignments.

Check the packed cartons periodically to ensure that they meet the quality standards. Inspect the sealing to make sure it is secure, the product quantity is correct, and the carton is properly formed and labeled (if labeling is part of the process).

4. Stopping the Machine

When it is time to stop the machine, press the "Stop" button on the control panel. The machine will complete the current packing cycle and then come to a halt.

Turn off the power switch of the machine. If the machine is going to be stopped for an extended period, it is recommended to unplug it from the power source for safety.

5. Safety Precautions

Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and closed-toe shoes when operating the machine.

Never attempt to repair or adjust the machine while it is running. Always turn off the power and wait for all moving parts to come to a complete stop before performing any maintenance or adjustments.

Keep the area around the machine clean and free of debris to prevent tripping hazards and ensure proper ventilation.

1. Food and Beverage Industry

In this industry, carton packing machines are used to pack a wide range of products such as snacks, cereals, canned foods, bottles of beverages, and frozen foods. For example, they can pack individual snack packs into larger cartons for distribution, or pack bottles of soda into cartons for shipping to retail stores.

2. Pharmaceuticals

Pharmaceutical companies use carton packing machines to pack tablets, capsules, bottles of liquids, and medical devices into cartons. These machines ensure that the products are packed in a sterile and secure manner, with proper labeling and documentation as required by regulatory authorities.

3. Electronics

In the electronics industry, carton packing machines are used to pack small components such as resistors, capacitors, and integrated circuits, as well as larger electronic devices such as smartphones, laptops, and televisions. The machines are designed to handle the delicate nature of electronic products, with anti-static features and precise handling mechanisms to prevent damage during the packing process.

4. Cosmetics and Personal Care

Cosmetic products such as creams, lotions, perfumes, and makeup items are packed using carton packing machines. These machines can create aesthetically pleasing packaging, with options for adding inserts, dividers, or decorative elements to the carton.

5. Household Goods

Household items such as detergents, soaps, cleaning products, and small appliances are commonly packed using carton packing machines. The machines can handle different sizes and weights of products, and can be configured to pack multiple items into a single carton for convenience.

Increased Productivity: Significantly higher packing speeds than manual labor (often 10x+).

Reduced Labor Costs: Automates a repetitive, labor-intensive task.

Consistency & Quality: Ensures uniform carton erection, loading, and sealing every time, reducing damage and errors.

Improved Hygiene: Minimizes human contact, crucial in food and pharma (especially in cleanrooms).

Enhanced Safety: Reduces worker strain and injury risks associated with manual packing.

Optimized Material Usage: Precise control over glue/tape application minimizes waste.

Space Efficiency: Often designed for compact integration into existing lines.

Traceability: Integration with production data systems for tracking.

Consider these critical factors:

Product Characteristics: Size, shape, weight, fragility, orientation, primary packaging (bottle, pouch, tray).

Carton Specifications: Blank size, style (RSC, HSC, tray, etc.), material (ECT value), required sealing method (glue, tape).

Required Output Speed (Carts/Minute or Hour): Match to upstream/downstream line speeds.

Level of Automation: Manual loading vs. automatic product infeed; basic vs. robotic loading; need for integrated labeling?

Integration: Compatibility with existing conveyors, upstream fillers/cappers, downstream palletizers. Footprint constraints.

Flexibility: How often will carton sizes/products change? Ease and speed of changeover.

Sealing Requirements: Glue (cold or hot melt), tape (type, position), need for inner flaps or special seals.

Hygiene/Safety Standards: Specific requirements (e.g., food-grade, washdown, ATEX for explosive atmospheres).

Budget: Purchase price, installation, consumables, maintenance, operating costs (energy). Consider Total Cost of Ownership (TCO).

Carton packing machines are indispensable for modern, efficient, and cost-effective packaging operations. By automating the complex process of erecting, loading, and sealing cartons, they deliver significant benefits in speed, consistency, labor savings, and product protection. Choosing the right machine requires careful consideration of your specific products, cartons, output needs, and budget. Proper operation and diligent maintenance are key to maximizing uptime and return on investment. By understanding the technology, mechanisms, and selection criteria outlined in this guide, you can make an informed decision to enhance your packaging line's performance.

Q1: What should I do if the carton is not erected properly?

A: First, check if the carton blanks are loaded correctly in the magazine and that they are of the correct size and type for the machine. Then, inspect the carton erecting unit for any loose parts or damaged components, such as vacuum cups or mechanical fingers. Adjust the settings on the control panel for carton size and erecting parameters if necessary. If the problem persists, contact the manufacturer's technical support for further assistance.

Q2: Why is the sealing quality poor?

A: There could be several reasons for poor sealing quality. Check the type and quality of the sealing material (e.g., tape, glue) being used. Ensure that the sealing unit is clean and that the application mechanism (such as the tape dispenser roller or glue nozzle) is in good condition. Adjust the sealing parameters on the control panel, such as the pressure and speed of the sealing process. If using glue, check the temperature of the glue (if applicable) to ensure it is at the correct setting for proper adhesion.

Q3: How can I improve the packing speed of the machine?

A: First, ensure that the machine is properly configured for the product and carton being used, with all parameters set optimally. Regularly maintain the machine to ensure that all components are in good working condition and that there are no mechanical issues that may be slowing it down. Train the operators to use the machine efficiently, including quick changeover procedures when switching between different packaging jobs. If possible, consider upgrading to a higher - speed model if your production volume requires it.

Susan Lin

Susan Lin

Hei , I am Susan Lin, the sales manger of Yile Machinery and I have been working for cartoning machine and case packing machine more than 15years.I would like to share my experience in this field. I am specialist of our packaging machine ,if you interesting our machine ,we can discuss and exchange technology of machine ,also give you good solution .

Reach me Now!GET A QUOTE

+86 13566127969

If you have any questions please contact us!