If you have any questions please contact us!

In the food industry, packaging plays a crucial role in preserving the quality, safety, and appeal of food products. A variety of machines are employed to achieve efficient and effective food packaging. Among these, the food cartoning machine is a key player. This article will focus on what a food cartoning machine is, its types, benefits, and answer some frequently asked questions about it.

A Food Cartoning Machine, often simply called a cartoner, is an automated or semi-automated machine designed to erect, load, and seal folding cartons (typically made of paperboard or corrugated cardboard) with food products. Its core functions involve:

Carton Erecting: Taking flat, folded carton blanks from a magazine and forming them into open boxes.

Product Loading: Precisely inserting the food product (or an inner package containing the product, like a bag, pouch, tray, or bottle) into the opened carton.

Closing & Sealing: Folding the carton flaps and securely sealing them, usually using glue, tape, or tucking mechanisms.

Optional Functions: Many cartoners also handle leaflet insertion (for instructions or coupons), date coding, batch coding, or checkweighing.

Cartoners are distinct from machines that form primary packaging (like filling pouches or sealing trays) and are typically positioned downstream in the packaging line after primary packaging is complete.

YL-60B Automatic Vertical Cartoning Machine is able to encase irregular bulk items that horizontal cartoning machine can not do. The cartoning machine is applicable for coffee capsules, wash powder, chocolate, pet food, penicillin bottle, perfume bottle, etc.

Encasing speed: 40-50boxes/min

Working pressure: ≥0.6mpa

Air consumption: 20m3/h

Power: 380V/50Hz

Motor power: 1.5kw

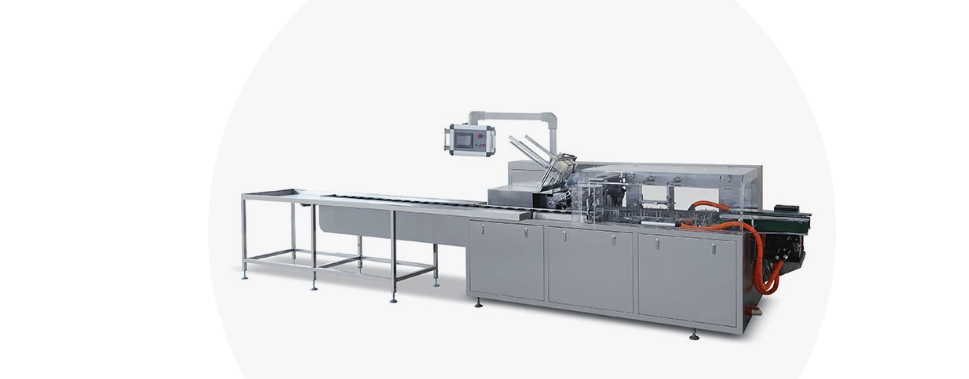

YL-60 Horizontal Cartoner is high technology product incorporates of pneumatic-photo-electro-mechanic. It is suitable for inserting tissue, pillow wrapped products, pharmaceutical products and food similar package into carton in a range.

Dimensions in mm: 4200×1350×1650(L×W×H)

Weight in kg: 1200

Steady production speed: 50cartons/min

Standard power supply: 380V / 50Hz three phase

Power consumption in KW: 1.5kw

Air consumption: 120-160L/min

YL-100 Tube Cartoning Machine can suitable for pharmaceuticals product into carton, such as liquid in bottle(glass/flat),The machine finished running by a series of photo-electro controller to make the machine stability and guarantee the packing quality.

Encasing Speed: 30-100 Boxes/min

Working Pressure: ≥0.6mpa

Air Consumption: 120-160L/min

Power: 220V/50Hz

Motor Power: 0.75Kw

Machine Weight: 1500Kg

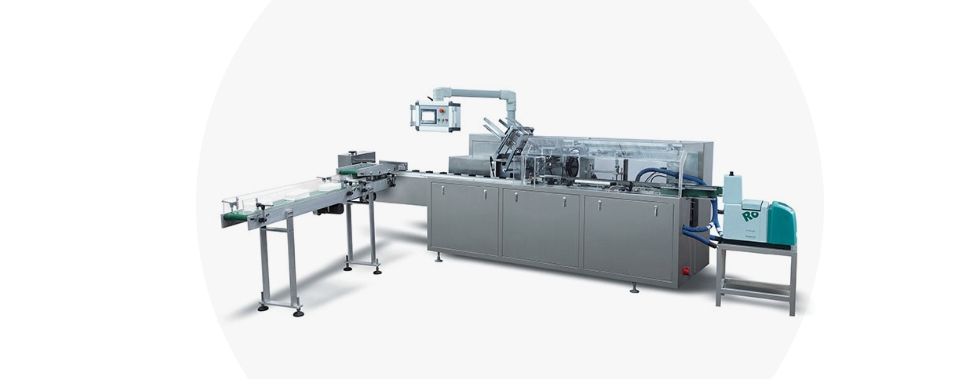

YL-40 Pouch Cartoning Machine is suitable for food product into carton, such as cake ,biscuit .It includes cantons opening and forming, products insert into carton, printing batch number, sealing or option hot-glue device.

Encasing speed: 30-40boxes/min

Working pressure: ≥0.6mpa

Air consumption: 20m3/h

Power: 380V/50Hz

Motor power: 1.5kw

Machine weight: 1600kg

1. Increased Productivity

Food cartoning machines can operate at high speeds, significantly increasing the packaging output compared to manual packaging. This is especially important for large-scale food production facilities that need to meet high demand.

2. Consistent Packaging Quality

These machines ensure that each carton is packed in a uniform manner, with the product placed correctly and the carton sealed properly. This helps in maintaining a high level of product presentation and reduces the risk of damage during transportation and storage.

3. Cost-Effective

Although the initial investment in a food cartoning machine may be relatively high, it can lead to long-term cost savings. By reducing the need for manual labor, minimizing packaging material waste, and increasing production efficiency, the machine can pay for itself over time.

4. Versatility

Food cartoning machines can be easily adjusted to handle different product sizes, shapes, and carton types. This makes them suitable for a wide range of food products, allowing food manufacturers to package multiple products using a single machine with minimal setup changes.

5. Improved Safety

Automated cartoning machines reduce the risk of human error and potential accidents associated with manual packaging. They also help in maintaining a clean and hygienic packaging environment, which is crucial for food safety.

Food cartoning machines are essential equipment in the food packaging industry, offering numerous benefits in terms of productivity, quality, cost-effectiveness, and versatility. By understanding the different types of food cartoning machines and their features, food manufacturers can make informed decisions to improve their packaging processes and meet the demands of the market.

Q1: What factors should I consider when choosing a food cartoning machine?

A: Key factors include: Product type, size, weight, and fragility; Required production speed (cartons per minute); Carton style and size range; Level of automation needed; Integration with upstream/downstream equipment; Available factory floor space; Budget; Hygiene requirements (e.g., washdown capability); Need for leaflet insertion or coding.

Q2: Can one cartoning machine handle different carton sizes?

A: Most modern cartoners are designed with changeover capabilities. Quick-change tooling (change parts for forming heads, flight bars, pushers) allows switching between different carton sizes and styles, though changeover time varies. Some high-speed machines may have limitations on the size range they can handle without significant downtime.

Q3: How difficult is it to maintain a food cartoning machine?

A: Maintenance complexity depends on the machine type and sophistication. Regular preventative maintenance (cleaning, lubrication, inspection) is crucial. Modern machines often have user-friendly HMIs for diagnostics. Availability of spare parts and local service support is a critical consideration. Simpler vertical cartoners are generally easier to maintain than complex horizontal or wrap-around systems.

Susan Lin

Susan Lin

Hei , I am Susan Lin, the sales manger of Yile Machinery and I have been working for cartoning machine and case packing machine more than 15years.I would like to share my experience in this field. I am specialist of our packaging machine ,if you interesting our machine ,we can discuss and exchange technology of machine ,also give you good solution .

Reach me Now!GET A QUOTE

+86 13566127969

If you have any questions please contact us!